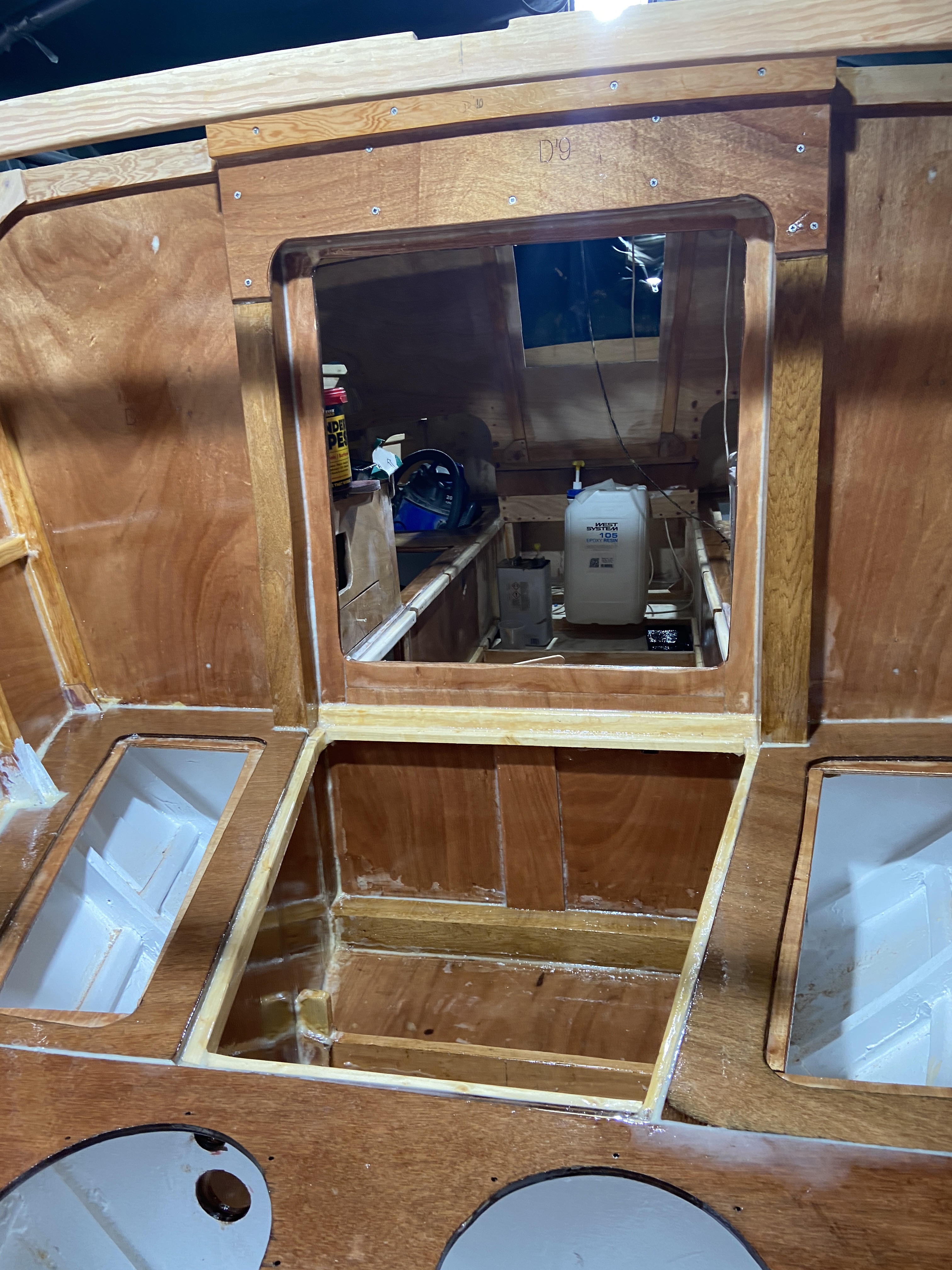

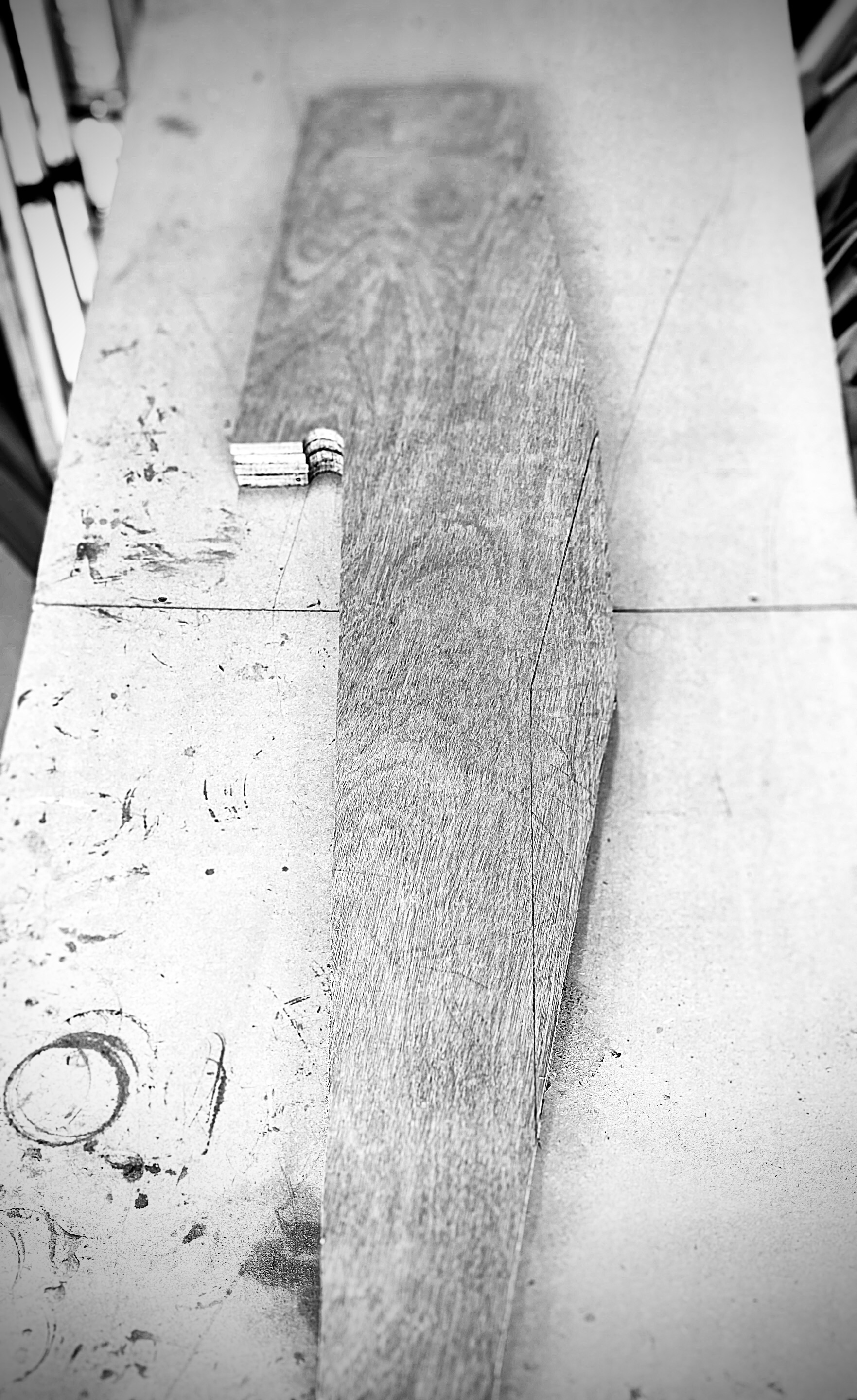

We managed to get all the deck panels glued on and sanded down a weekend or so ago. A few bits of tidying up but generally looks very smart. Happy builder.

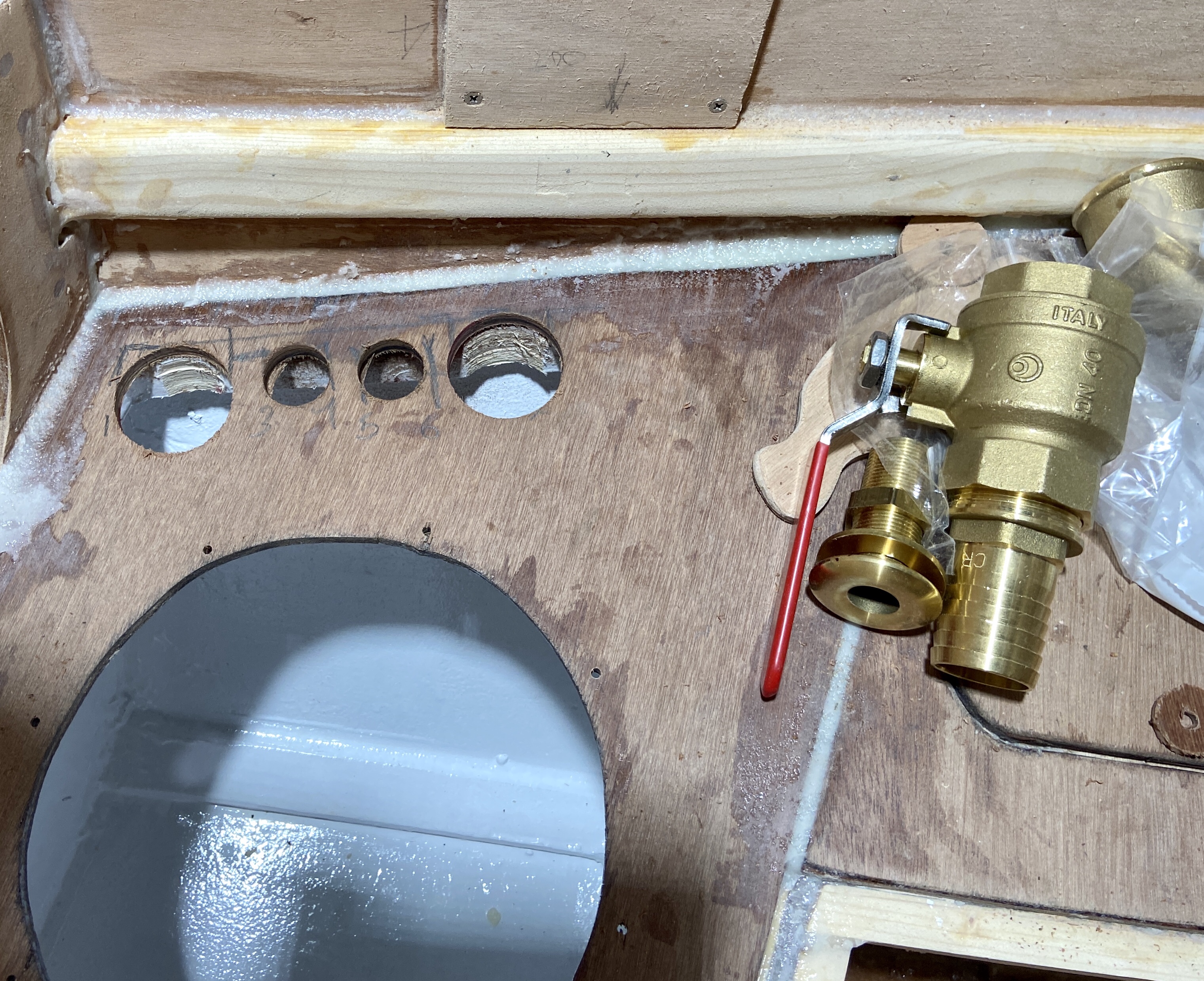

Onto cutting the hatch and vent holes next. Then need to make some decisions on the portlights for the shearstrakes and the observation pod. Need to get these all organised so that I can fibreglass the deck. I would like to get this done before Winter bites too deep but may now struggle for time as essentially limited to weekend building.

Probably turn the boat around so I can get to the cockpit more easily to do the fitting out there. Need to start pouring the skeg. I have the mould, and the bolts, just need to start building up the epoxy.

A couple of points of motivation. The fleet for the first Transac race have arrived in Lanzarote and are preparing for the Atlantic itself. Some great achievements to get this far. Good luck to all of them.

This was never my goal. I was building towards to Azores race that was in the calendar when the class was first announced but is not happening now. So I’ll do some coastal sailing next year and see what happens in 2023, maybe a Jester Race. Who knows!

Oh! And my Mast arrived!! Better get something to mount it on then.